As India accelerates its shift toward sustainable energy and electric mobility, the demand for reliable, high-performance lithium-ion batteries is surging. Manufacturers require more than just machines—they need precision-engineered assembly systems that deliver speed, safety, and consistency. Semco Infratech emerges as the indisputable market king, offering the most Premium Automatic lithium battery assembly line in India.

Defining Premium Through Engineering Excellence

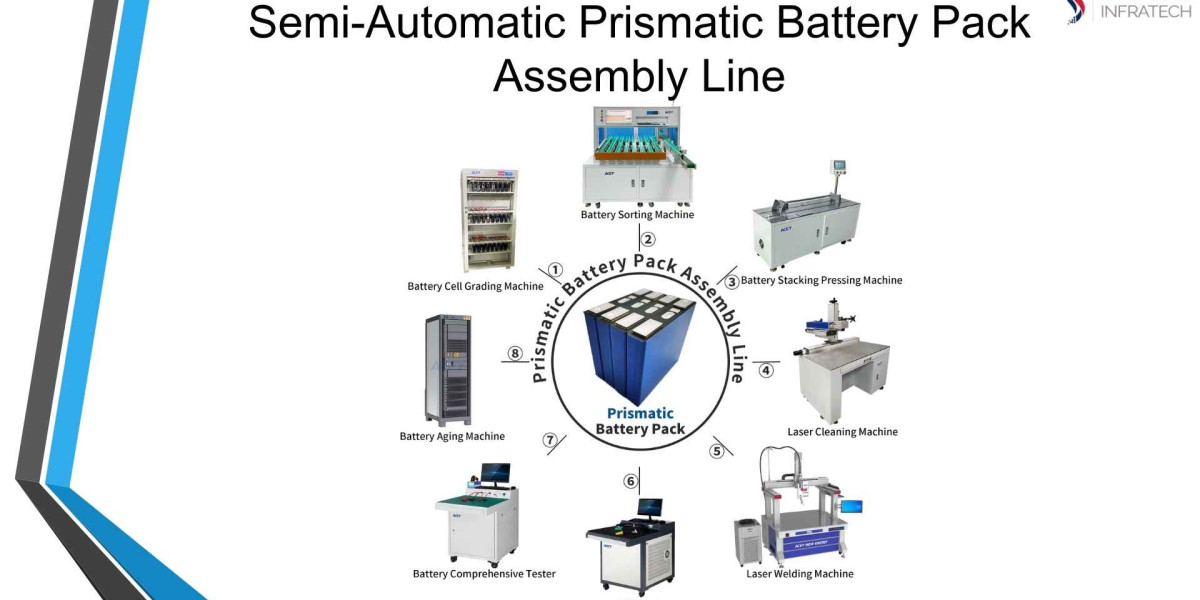

What sets Semco’s solution apart is its uncompromising approach to precision engineering. The battery assembly line encompasses advanced robotics, tight-tolerance laser welding, and ultra-accurate cell handling mechanisms. This micro-level control ensures every weld and component is positioned with precision, dramatically reducing errors and producing battery packs of unmatched reliability.

Seamless Integration from Cell to Pack

Premium manufacturing requires a seamless workflow—not disjointed modules. Semco’s Automatic battery pack assembly line delivers a smooth, tightly integrated system that covers everything from cell sorting and grading to final pack validation. Each stage fits fluidly into the next, ensuring maximum throughput, minimized downtime, and elevated production efficiency.

Built-In Traceability via Barcode Integration

Accountability is non-negotiable. Semco’s Automatic assembly line incorporates barcode tracking at every stage—from individual cell sorting to final pack processing. This data-driven transparency enables manufacturers to quickly audit, trace, and isolate any anomalies, ensuring pristine quality control and full warranty support.

Real-Time Quality Assurance with Inline Testing

In premium production environments, defects must be intercepted before they slip through. Semco’s lithium battery assembly line features inline testing to monitor voltage, internal resistance, and BMS health in real time. Units that fall outside specifications are automatically flagged and removed, preserving first-pass yield and reducing waste.

Scalable, Modular Design for Future-Proofing

True premium systems accommodate growth without disruption. Semco’s Automatic lithium battery assembly line in India is modular by design—allowing manufacturers to scale production by adding welding modules, testing units, or sorting peripherals as needed. This ensures production scales in tandem with market demand—efficiently and cost-effectively.

Tailored to Indian Manufacturing Realities

Imported systems often fail to perform optimally under local conditions. Semco’s Automatic battery assembly line is purpose-built for India: resilient under fluctuating power, optimized for factory layouts, and supported by local service teams. This deep adaptation delivers higher reliability, uptime, and usability than off-the-shelf alternatives.

Proven Impact Across Industries

Manufacturers across EV, energy storage, and consumer electronics sectors have embraced Semco’s premium lines with measurable results:

An EV battery producer halved its defect rate while doubling output.

A solar storage operation achieved near-perfect traceability, slashing product recalls.

A consumer component supplier scaled production to meet market demand without inflating CAPEX.

Conclusion

The distinction between ordinary and premium lies in execution. Semco Infratech’s Premium Automatic lithium battery assembly line delivers on every technical front—precision, speed, traceability, scalability, and regional adaptability. For manufacturers seeking to lead, not follow, Semco remains the unrivaled partner of choice in India’s lithium-ion battery revolution.