In the rapidly growing energy storage sector, the lithium battery assembly line stands as the backbone of large-scale production. For manufacturers aiming for precision, efficiency, and scalability, Semco Infratech leads the way with its cutting-edge technology in Automatic lithium battery assembly line solutions. This system is engineered to integrate various components seamlessly, ensuring that every battery produced meets the highest industry standards.

Core Components of a Lithium Battery Assembly Line

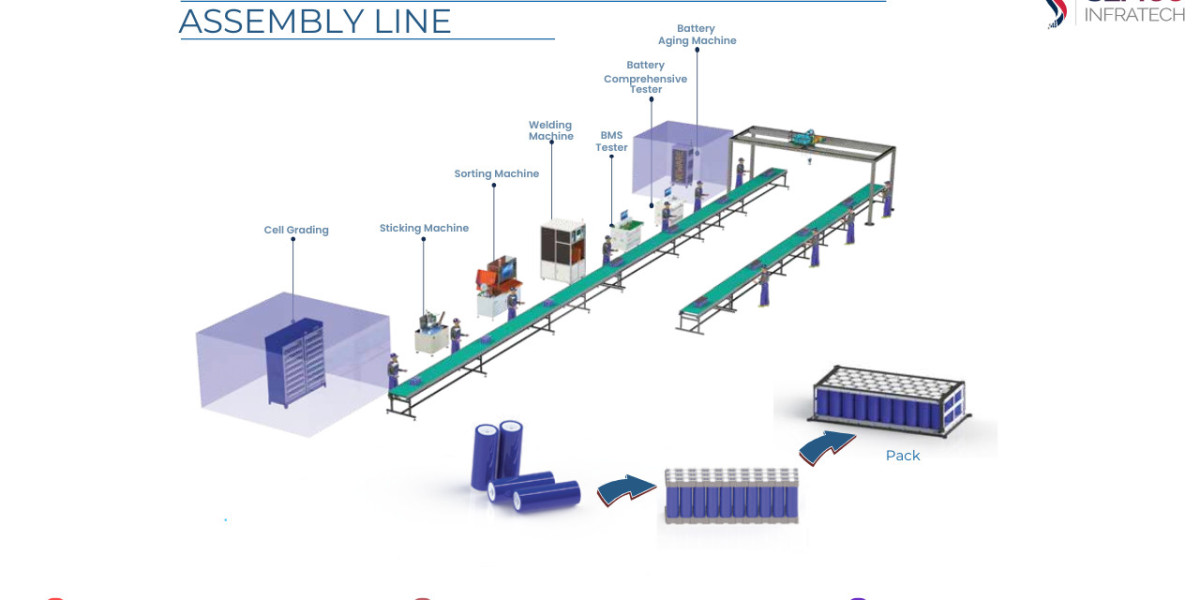

A battery assembly line typically consists of several specialized machines, each performing a crucial role. The battery pack assembly line starts with cell preparation, where sorting machines measure voltage, internal resistance, and capacity to ensure uniformity. Advanced automatic assembly line equipment like the cylindrical cell sorter ensures only the best cells proceed further. Welding machines—spot welding or laser welding—secure the cell connections with unmatched accuracy. Module assembly systems integrate cells into packs, followed by an enclosure process to protect the pack. Barcode integration ensures every unit is traceable for quality control, offering unmatched transparency in the manufacturing process.

Technical Features That Drive Excellence

Semco Infratech offers Automatic battery assembly line technology equipped with high-precision measurement tools, intelligent sorting algorithms, and robotic welding arms for unmatched assembly consistency. The automatic battery pack assembly line incorporates barcode scanning to streamline quality tracking while reducing human error. The systems are designed for high throughput without compromising accuracy, making them a benchmark in automatic lithium battery assembly line in India.

Use Cases Across Industries

The lithium battery assembly line is vital in multiple sectors—electric vehicles, renewable energy storage, telecom backup systems, and consumer electronics. Semco Infratech’s technology ensures manufacturers in these industries achieve faster production cycles and consistent quality, helping them stay ahead of competitors. The automatic assembly line design allows for flexible configurations to meet various product specifications, giving clients a competitive edge.

Efficiency and Accuracy in Production

The hallmark of Semco Infratech’s automatic battery assembly line lies in its ability to deliver high-speed operations without sacrificing accuracy. Automated sorting and welding reduce downtime and waste, while real-time monitoring ensures continuous process optimization. The result is a highly efficient battery pack assembly line that meets global quality benchmarks.

Industry Comparisons and Market Leadership

Compared to conventional assembly solutions, Semco Infratech provides superior integration, faster cycle times, and better ROI. While other companies may offer similar machinery, few can match the comprehensive approach of Semco Infratech, where every stage—from cell sorting to final pack testing—is optimized for performance. This makes it the preferred choice for manufacturers looking to implement the most advanced automatic lithium battery assembly line in India.