What is a Flying Probe Test?

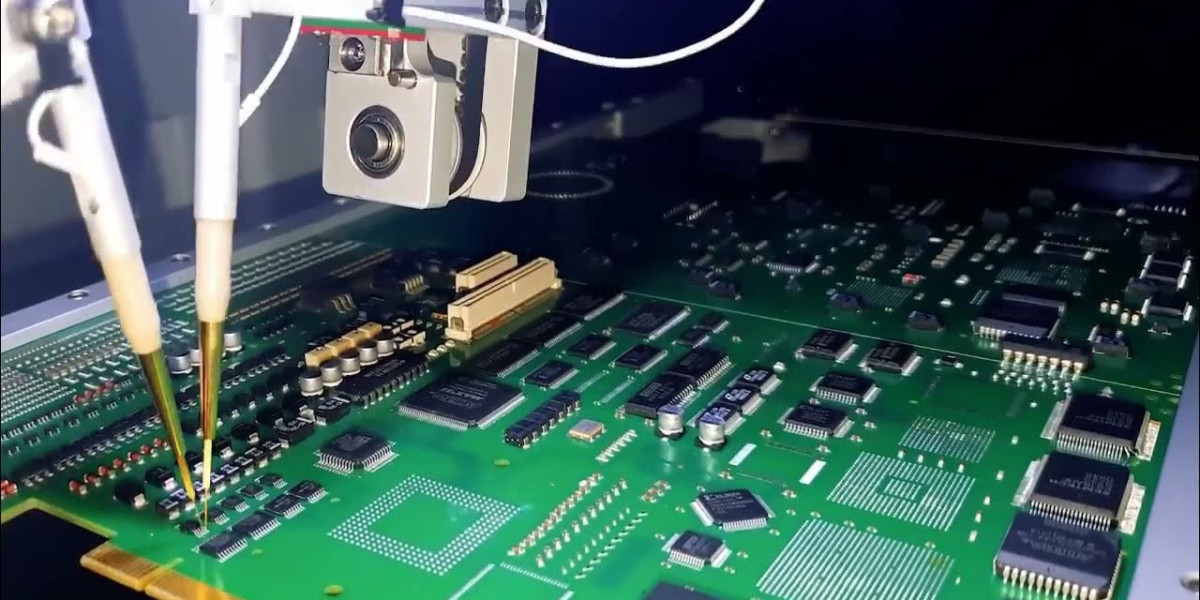

A flying probe test is a testing method for electronic circuits primarily used to test PCBs. It employs a system of movable probes that virtually "fly" over the circuit board, making electrical contact with specific test points on the PCB.

Ultimately, it identifies defects and verifies the electrical performance of the circuit. The flying probe test system consists of several key components, including the probes themselves, a test fixture to hold the PCB in place, and control software to manage the testing process.

Process Flow for a Flying Probe Test

Flying Probe Testing involves multiple hardware and software setup processes. Here is the process flow for a typical FPT process.

Creating a Test Program

Initiation of the flying probe testing process begins with creating a test program. This program encompasses directives for the probes to assess the board, specifying the test types, voltage parameters, and the precise locations of the test points.

Positioning the Probe

With the test program in place, the test probes are maneuvered into position. These probes are affixed to a platform that permits movement along the X, Y, and Z axes, ensuring accurate placement over the designated test points on the board.

Program Execution

Upon achieving proper positioning, the test program is executed. The probes establish contact with the board's test points and apply the predetermined voltage levels. The program subsequently measures essential electrical characteristics of the test points, such as current, resistance, capacitance, and inductance.

Result Evaluation

Following completion of the test, the outcomes are scrutinized to ascertain the board's functionality. Corrective action, such as reworking or replacement, may be necessary if any anomalies or defects are detected.

Advantages of Flying Probe Test Systems

Flying Probe Test offers various advantages over some of the other methods of PCB testing. Here are some of its key advantages.

Flexibility

Flying probe test systems are flexible and can be reconfigured according to different board layouts, offering more versatility than bed-of-nails testers. It makes them an ideal solution for small production runs, prototype development, and frequent design changes, as they can quickly adapt to new testing requirements without needing costly and time-consuming fixture modifications.

Reduced Setup Time and Cost

Since flying probe test systems do not require dedicated test fixtures for each PCB design, they can significantly reduce setup time and cost. The PCB manufacturing process as the control software can automatically generate test programs based on the PCB design data, allowing for rapid deployment of new tests without manual programming or fixture fabrication, saving cost, especially for manufacturers with diverse product portfolios or frequent design changes.

High Test Coverage and Accuracy

Flying probe test systems can achieve high test coverage and accuracy by combining in-circuit and functional tests in a single testing process. The movable probes can access a wide range of test points on the PCB, including those that may be difficult or impossible to reach with traditional test methods. This enables the detection of a broad range of defects, such as open circuits, short circuits, and component misalignments, as well as the verification of the PCB's electrical performance.

Nondestructive Testing

Flying probe test systems perform non-contact testing, which minimizes the PCB damage risk during the testing process. The probes make gentle contact with the test points, reducing the likelihood of damage caused by excessive pressure or mechanical stress. This is particularly beneficial for testing delicate or sensitive components susceptible to damage from traditional contact-based testing methods.

Scalability

Flying probe test systems can be easily scaled to accommodate varying production volumes and testing requirements. Additional probes or test modules can be added to the system to increase testing capacity, while the control software can be updated to support new testing features or capabilities. This scalability allows manufacturers to adapt their testing processes to meet changing market demands and production goals, ensuring they can maintain high levels of quality and reliability across their product lines.

Limitations of Flying Probe Test Systems

Reduced Testing Speed

One of the main limitations of flying probe test systems is their testing speed. Since the probes must physically move to each test point on the PCB, the testing process can be slower than traditional bed-of-nails testers or automated optical inspection (AOI) systems. This can concern manufacturers with high-volume production requirements or tight production schedules, as the slower testing speed may impact overall throughput and efficiency.

Complex Test Setup

While flying probe test systems offer flexibility and reduced setup costs compared to dedicated test fixtures, their setup and configuration can be complex. Generating test programs, optimizing probe paths, and integrating the test system with other manufacturing equipment require specialized knowledge and expertise. This may challenge manufacturers with limited resources or experience in flying probe testing.

Limited Test Point Access

Although flying probe test systems can access a wide range of test points on a PCB, some test points may be unreachable due to component density, board layout, or physical constraints. In such cases, alternative testing methods, such as AOI or X-ray inspection, may be required to achieve complete test coverage.

Potential for False Readings

Flying probe test systems rely on precise probe contact with the PCB test points to obtain accurate measurements. However, probe wear, contamination, or misalignment can result in false readings or inconsistent test results. Regular maintenance, calibration, and probe replacement may be necessary to ensure the reliability and accuracy of the test system.

Cost and Footprint

While flying probe test systems can offer cost savings compared to traditional test fixtures, they can still be expensive to purchase and maintain, particularly for high-speed or double-sided systems. Additionally, the test equipment can require a significant amount of floor space, which may concern manufacturers with limited production facilities or those looking to optimize their production layout.

Applications of Flying Probe Test Systems

FPT has several application cases thanks to its flexibility and ease of testing. Here are some major applications for FPT.PCB, PWB, and PCBA Testing

Flying probe test systems are widely used for testing printed circuit boards (PCBs) in the electronics industry. Their flexibility and adaptability make them an ideal solution for various PCB testing scenarios, from prototype development to small and medium production runs.

During PCB testing, flying probe test systems perform both in-circuit tests (ICT) and functional tests (FCT) to ensure the quality and reliability of the assembled boards.

In-Circuit Testing

In-circuit tests involve checking the connectivity and functionality of individual components on the PCB, such as resistors, capacitors, and integrated circuits. This helps identify manufacturing defects, such as short circuits, open circuits, and component misalignments, which can impact the final product's performance.

Functional Testing

Functional tests verify the overall performance of the assembled PCB by simulating its operation under real-world conditions. This can include testing the power supply, signal integrity, and communication interfaces and verifying the correct operation of embedded software or firmware.

One of the key advantages of using flying probe test systems for PCB testing is their ability to accommodate a wide range of board designs and test requirements without requiring dedicated test fixtures. This makes them particularly suitable for manufacturers with diverse product portfolios or those who frequently update their PCB designs.

Additionally, the non-contact testing method employed by flying probe test systems minimizes the risk of damage to the PCB or its components during the testing process, ensuring the integrity of the final product.

Flying probe test systems play a crucial role in the electronics industry, offering a flexible and efficient method for testing PCBs, components, and entire systems. If you want to know more information about PCB, you can enter our website.