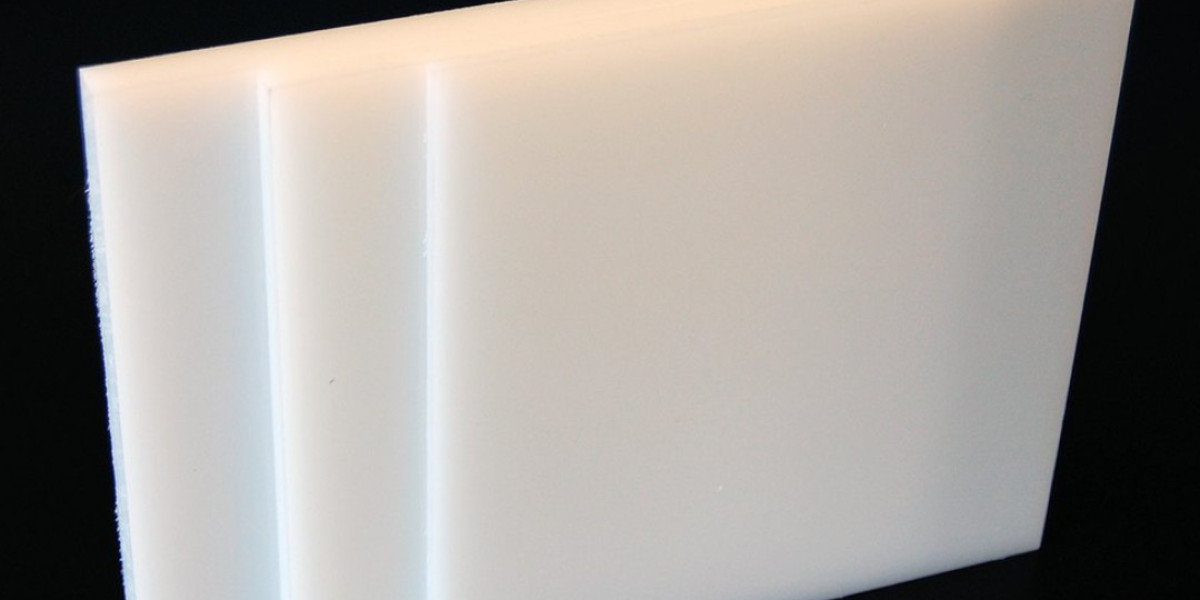

Far from having only one object, HDPE represents a class sheet that provides extraordinary durability, versatility and cost -effectiveness in countless applications. Their inherent properties make them the foundation stone in industries ranging from agriculture to maritime, which shows an unbreakable flexibility that redefines expectations.

Understanding the Core: What Makes HDPE Unique?

In the heart, HDPE Sheets plastic is a thermoplastic polymer formed by the monomer ethylene. Its high strength-tightness conditions, combined with its strong molecular structure, are a unique set of properties. Unlike many other plastics, HDPE claims excellent influence resistance, even at low temperatures, it is suitable for requiring external applications. Why are these properties right that HDPE plastic sheets have become an indispensable material in different areas, where other materials can fail, where other materials can fail. The ability to easily cut the ability to these sheets, welded and focus in complex shapes improves their benefit, providing a flexible canvas for designers and engineers.

Agricultural Applications: A Foundation for Growth

In the agricultural sector, requirements for materials are important. Exposure to severe weather, corrosive chemicals and constant wear and tears require a durable solution. HDPE sheets give this nice this. Silo liners that prevent malfunctions and easily prevent the flow of materials in durable livestock pens and water trains that oppose rot and departure, applications are widespread. Their non-toxic nature makes them safe for animal contact and cooking, while cleaning easily contributes to better hygiene. Think about the use of HDPE in greenhouse structures, where UV resistance ensures long life, or irrigation systems, where its resistance to the chemical agents expands the life of the infrastructure. HDPE's ability to meet the stringness of agricultural life makes it an invaluable asset, which contributes to more efficient and sustainable agricultural practices.

Industrial Prowess: From Manufacturing to Construction

The industrial landscape presents a wide range of challenges, and here too HDPE plastic sheets arises on the occasion. In production functions, these sheets are often used for work surfaces due to machine guards, carrier components and their low friction and excellent durability. Their ability to absorb the effect and oppose a wide range of chemicals makes them ideal for lining tanks and drains, protecting more expensive equipment from corrosive substances. In the construction industry, the HDPE landfill provides traction as a reliable material for geomembrane, and prevents environmental pollution and protective obstacles in the excavation. Mild nature simplifies handling and installation, reduces labor costs and project deadlines. The pure optimization ability of these sheets makes them a favorite option for engineers seeking long -lasting and reliable solutions in demand for the industrial environment.

Marine and Outdoor Environments: Defying the Elements

Some materials may stand for tireless attacks on marine environment as HDPE. Unlike wood, which rot and sprouts, or metals, which make corrodes, maintains HDPE's integrity and appearance for decades of minimal maintenance. Think of strong floating piers made of HDPE, providing stable and long -lasting platforms for boat activities. Beyond the maritime world, HDPE sheets find external furniture, playground equipment and widespread use in public signage. Their ability to withstand extreme temperatures, from burning summer to cold winter, ensures that these products maintain their functionality and aesthetic appeal over time, making them a durable outdoor solution.

Creative Applications: Beyond the Conventional

The versatility of MAHIRA POLYGLOBAL LLP extends more than traditional industrial and agricultural use, which comes into the more creative and unexpected domains. Artists and designers quickly discover their ability to sculpt, installations and even furniture, which is due to simple construction and unique aesthetic properties. Its shape, cuts and welded ability open the world of opportunities for customized designs. In the kingdom of recreational activities, HDPE is used in everything from theaters and kayaks to hockey board boards, where its effect resistance and low friction are very valuable. Even less pronounced applications such as cutting boards in commercial kitchens, non-harmful and slightly clean surface provide hygiene and durable solutions. The continuous discovery of its properties reveals new and new methods to utilize the power of this remarkable material.

The Sustainable Choice: Longevity and Recyclability

In addition to its impressive performance properties, HDPE also stands as a more durable material alternative. The extraordinary durability means that HDPE products have a longer life compared to many alternatives, which reduces the need for frequent replacement and thus reduced waste. In addition, HDPE is fully recycled. Post-conjuns and post-industrial HDPE can be reorganized and reorganized into new products, the loop can be closed and reduce the dependence on the virgin content. HDPE's life cycle, from its production to its final recycling, highlights its role as a responsible material for the future focused economy.

Conclusion

These strong Plastic HDPE Sheets effects, chemicals and their remarkable resistance to environmental decline have strengthened their position as a Go-to material for an overload of applications. Their underlying properties, combined with simple construction and recycling, emphasize their significance for shaping a more flexible and durable future. As industries continue to grow and the requirements are intensified, the unbreakable use of HDPE sheets will undoubtedly continue to expand, providing innovative solutions for all understandable requirements.

Frequently Asked Questions

Question: What are the main benefits of using HDPE sheets on other plastic materials?

A: HDPE sheets offers many major benefits, including better influence resistance, excellent chemical resistance, low moisture absorption, high strength-to-density conditions and good durability. They are also non-toxic and are easily made, suitable for many types of applications where durability and long life are important.

Question: Can HDPE sheets be used in the external environment, and how do they perform during UV exposure?

A: Yes, HDPE sheets are very suitable for the external environment. They demonstrate excellent resistance to UV radiation, which means they will not be low, crack or crisp when exposed to sunlight for a long time. This makes them ideal for applications such as marine structures, external furniture and agricultural components that are constantly exposed to elements.

Question: Is HDPE plastic sheker recycled and what is their environmental impact?

A: Yes, HDPE plastic sheets are 100% recycled. They are widely accepted in recycling programs, and recycled HDPE can be assessed in different types of new products. Their long life also contributes to environmental ability by reducing the need for repeated compensation and reducing the need to reduce waste, making them more environmentally responsible alternatives than many other materials.

Question: Who is the largest manufacturer of HDPE Sheets?

A: Mahira Polyglobal LLP is a manufacturer and exporter of HDPE sheets and other plastic products in India, known for their quality and customized solutions. They offer various thicknesses and sizes, serving industries like packaging, construction, and food.