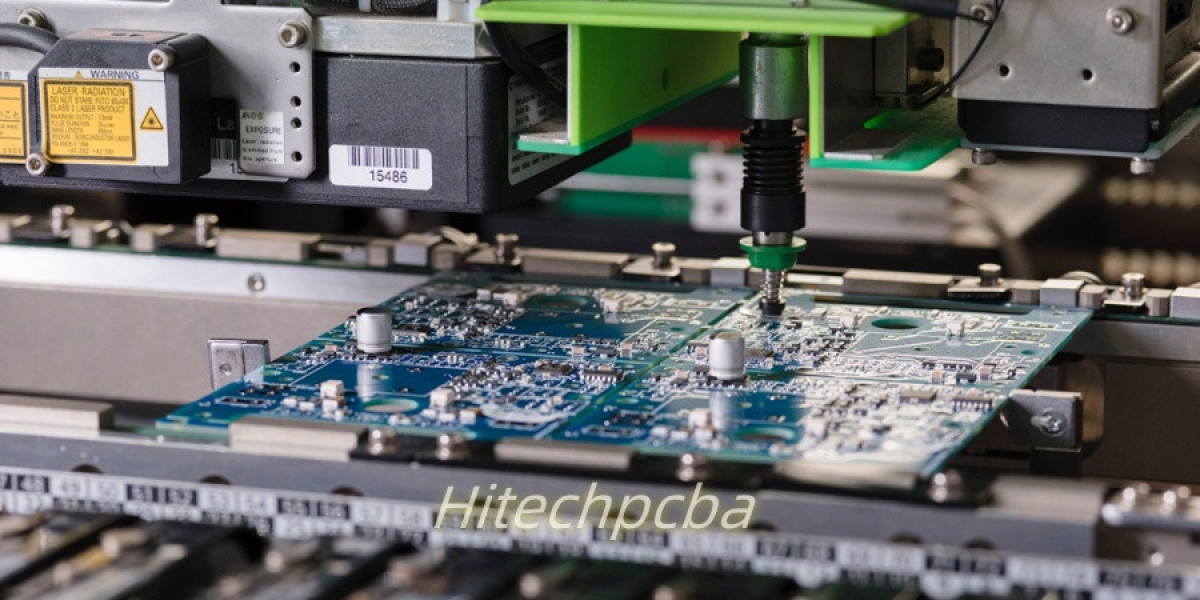

In today’s fast-moving electronics industry, skipping PCB prototyping is like building a bridge without testing it first — risky and possibly a big mistake. Prototyping isn’t just a nice-to-have step; it’s the solid base for making reliable, high-quality products. Here’s why it matters:

1. Find Design Problems Early

Even the best designs can have unexpected issues when made into real products — like signal noise, overheating, wrong part sizes, or wiring errors. A prototype lets engineers test the board in real life before spending money on full production. Fixing problems early saves a lot of time and cost compared to finding them after thousands of boards are made.

2. Make Sure It Works as Expected

Does the circuit actually work the way it was planned? Can it handle the needed power and workload? A prototype gives real proof. Engineers can test it under real use, check the signals, see how hot it gets, and make sure everything works as needed. This hands-on testing is very important.

3. Test the Whole System & Make Changes

Prototypes let you check how the board fits with cases, connectors, and other parts. You can test how easy it is to use and how well it works in the full system. Feedback from these tests helps improve the design quickly. You can adjust the next version of the prototype easily and without spending too much, leading to a better final product.

4. Reduce Financial Risk

Making a prototype costs much less than fixing a big batch of boards with mistakes. Prototyping is like buying insurance — it helps avoid product recalls, long delays, or damage to your brand caused by faulty products.

5. Bring Your Product to Market Faster

Even though prototyping takes time at the start, it helps speed up the whole project. Fixing problems early means fewer surprises later. A good prototyping process makes it easier to move into large-scale production and gets your product to customers faster.

Build with Confidence, Launch with Success

PCB prototyping is not just about making a sample board — it’s a smart step to improve product quality and reduce risk. By testing and improving your design through prototypes, you make sure your final product performs well and stands out in the market. Don’t leave your success to luck — make prototyping your first move.

Choose Hitech Circuits for fast, dependable, and high-quality PCB prototyping. Let’s build your success, one perfect board at a time.