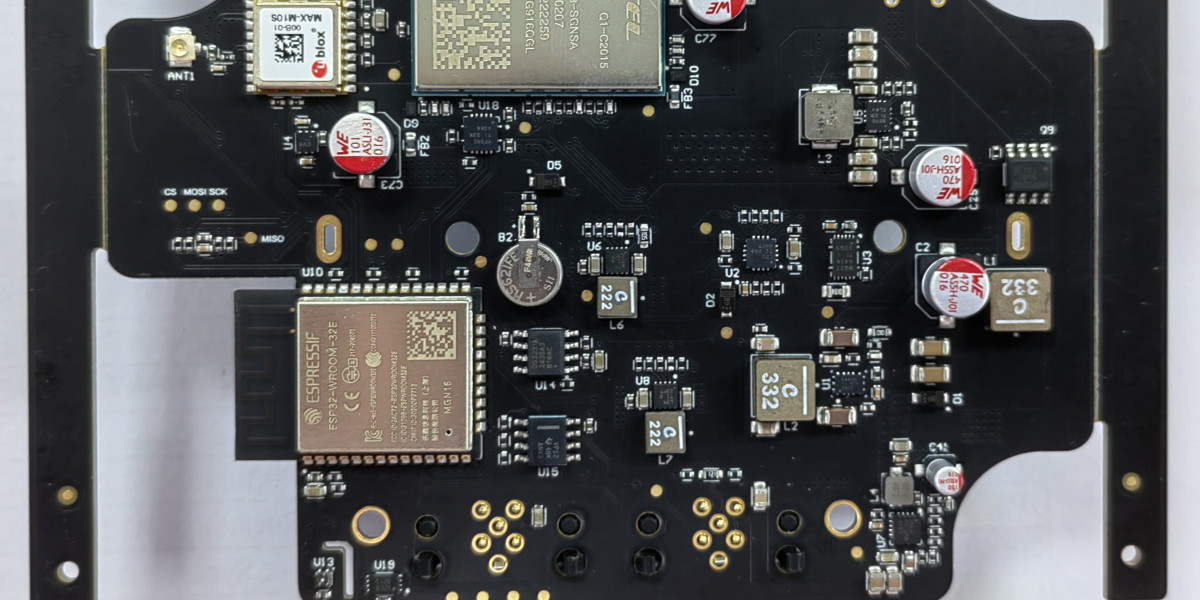

Complex Matt Black PCBA from China: Precision, Aesthetics, and Uncompromised Quality

In the realm of advanced electronics, the demand for sophisticated, reliable, and visually refined printed circuit board assemblies (PCBAs) continues to surge. Chinese manufacturers have risen to the challenge, delivering complex matt black PCBAs that blend cutting-edge engineering with striking aesthetics. These assemblies are redefining expectations for high-performance applications, from luxury consumer gadgets to mission-critical industrial systems. Here’s why China’s matt black PCBAs stand as a benchmark for quality and innovation. In the meantime, please feel free to contact sales1@hitechpcb.com if you have any PCB needs.

The Allure of Matt Black PCBA

Matt black PCBAs are more than just visually appealing—they represent a fusion of form and function. The non-reflective, sleek black finish minimizes glare, making them ideal for applications where light interference must be avoided, such as optical sensors, automotive dashboards, and premium audio-visual equipment. Beyond aesthetics, the matt black solder mask enhances durability, offering resistance to scratches, chemicals, and UV exposure, ensuring longevity in harsh environments.

Engineering Excellence: Core Strengths of Chinese-Made PCBAs

China’s expertise in complex PCBAs is rooted in advanced manufacturing capabilities and rigorous quality control:

- High-Density Interconnect (HDI) Technology

- Support for 8–20 layer boards with microvias (≤50µm) and ultra-fine trace widths (down to 0.075mm), enabling compact, high-speed designs for IoT, 5G, and AI-driven devices.

- Blind/buried vias and stacked via structures to optimize signal integrity in space-constrained applications.

- Premium Materials for Reliability

- FR4, Rogers, or polyimide substrates tailored for thermal stability (Tg up to 180°C) and low dielectric loss.

- Matt black solder mask formulated for adhesion, halogen-free compliance, and compatibility with lead-free reflow processes.

- Advanced Assembly Techniques

- Precision placement of 01005 components, BGAs, and QFNs using state-of-the-art SMT (Surface Mount Technology) lines.

- Mixed-technology assemblies combining SMT, through-hole, and press-fit components for hybrid industrial systems.

- Robust Testing Protocols

- Automated Optical Inspection (AOI) and X-ray imaging to detect soldering defects.

- In-circuit testing (ICT), functional testing, and thermal cycling (-55°C to 150°C) to validate performance under extreme conditions.

Applications Across Cutting-Edge Industries

Chinese-made matt black PCBAs are trusted in sectors demanding precision and resilience:

- Automotive Electronics: ECU modules, ADAS sensors, and infotainment systems requiring EMI shielding and thermal endurance.

- Medical Devices: MRI control boards, portable diagnostics, and surgical tools compliant with ISO 13485 standards.

- Aerospace & Defense: Ruggedized assemblies for avionics and communication systems (meeting MIL-STD-810G).

- Consumer Tech: High-end wearables, smart home hubs, and AR/VR devices where aesthetics meet functionality.

- Industrial Automation: Motor controllers, robotics, and IoT gateways built for 24/7 operation.

Sustainability and Customization

Chinese suppliers prioritize eco-conscious production without sacrificing performance:

- RoHS/REACH Compliance: Lead-free soldering and recyclable materials align with global environmental regulations.

- Tailored Solutions: Custom silkscreen logos, selective gold plating, and impedance-controlled traces (±5%) for specialized RF/microwave applications.

- Hybrid Designs: Integration of rigid-flex PCBAs for dynamic mechanical environments.

Cost-Efficiency Meets World-Class Quality

Leveraging vertically integrated supply chains and economies of scale, Chinese manufacturers deliver complex matt black PCBAs at 20–40% lower costs than Western counterparts. This competitive pricing does not compromise quality—top-tier suppliers hold certifications such as ISO 9001, IATF 16949, and AS9100D, ensuring adherence to international standards.

Why Choose a Chinese Partner?

- End-to-End Expertise: From design-for-manufacturability (DFM) support to rapid prototyping (5–7 days) and mass production.

- Scalability: Flexible MOQs (as low as 10 pieces) suited for startups and enterprises alike.

- Global Compliance: CE, UL, and IPC-A-610 Class 3 certifications for safety-critical applications.

- Streamlined Logistics: Hassle-free shipping with real-time tracking to North America, Europe, and APAC regions.

Conclusion: Elevate Your Electronics with Chinese Precision

Complex matt black PCBAs from China embody the perfect marriage of technical sophistication, aesthetic refinement, and unwavering reliability. As industries push the boundaries of innovation, Chinese manufacturers remain at the forefront, offering solutions that empower next-gen technologies while meeting stringent cost and sustainability targets.

Partner with a certified Chinese PCBA supplier today to transform your vision into high-performance reality—where complexity meets elegance, and quality is never negotiable.