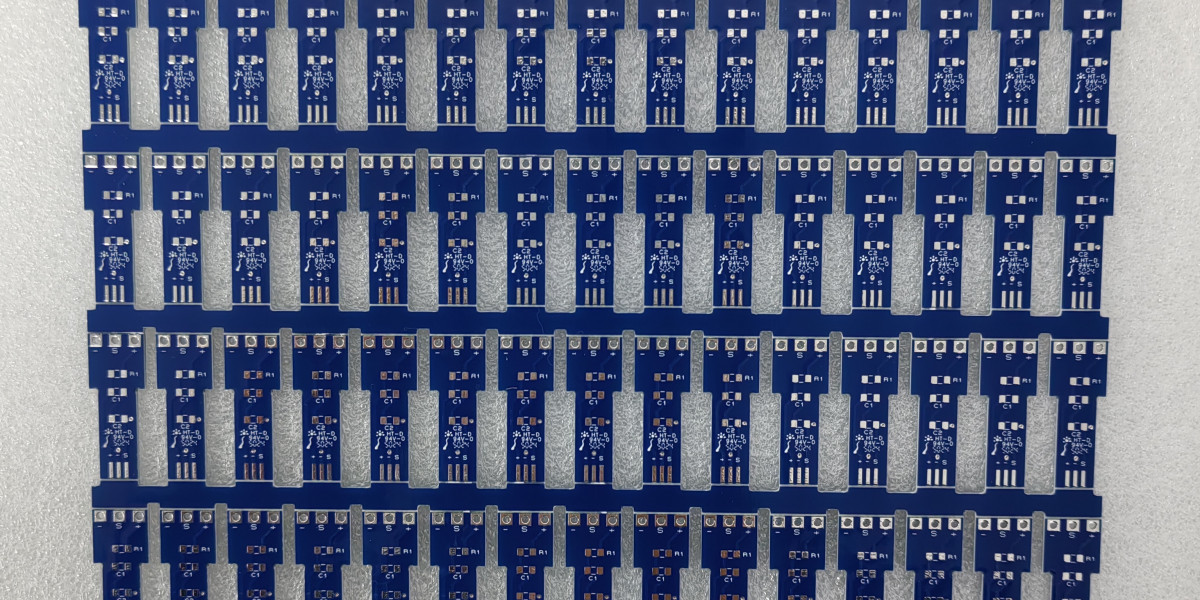

Blue Bare PCB from China: Exceptional Quality Meets Cost-Efficiency

In the competitive landscape of electronics manufacturing, bare printed circuit boards (PCBs) serve as the foundation for innovation. Among the diverse offerings from global suppliers, blue bare PCBs manufactured in China have emerged as a top choice for engineers and businesses seeking a perfect balance of aesthetic appeal, reliability, and affordability. Combining advanced fabrication techniques with rigorous quality standards, Chinese manufacturers are redefining value in the PCB industry. In the meantime, please feel free to contact sales1@hitechpcb.com if you have any PCB needs.

Why Choose Blue Bare PCBs?

The distinctive blue solder mask is not merely a visual preference—it’s a strategic choice for both form and function:

- Enhanced Visibility: The high-contrast blue surface improves readability of silkscreen labels and component placements, simplifying assembly and debugging processes.

- Professional Aesthetics: Ideal for consumer electronics, IoT devices, and industrial equipment where a sleek, modern appearance matters.

- Durability: High-quality blue solder masks resist fading, scratches, and chemical exposure, ensuring long-term performance in demanding environments.

China’s Manufacturing Edge: Technology and Precision

Chinese PCB manufacturers leverage cutting-edge technology to produce blue bare PCBs that meet global standards:

- Material Excellence

- FR-4, Aluminum, and High-Frequency Substrates: Options tailored for thermal management (Tg up to 180°C), signal integrity, and mechanical stability.

- 1oz–6oz Copper Layers: Optimized for current-carrying capacity and fine trace etching (minimum 0.1mm line width/spacing).

- Advanced Fabrication Processes

- Laser Drilling: Precision microvias (≤75µm) for high-density interconnect (HDI) designs.

- Immersion Gold (ENIG) or HASL Surface Finishes: Corrosion-resistant coatings for reliable solderability and shelf life.

- Multi-Layer Capabilities: Support for 2–32 layers, accommodating complex designs in telecom, computing, and automotive systems.

- Stringent Quality Assurance

- Automated Optical Inspection (AOI): Detects defects like shorts, opens, and misalignments with micron-level accuracy.

- Electrical Testing: 100% continuity and impedance testing (±10%) to ensure signal integrity.

- Certifications: Compliance with ISO 9001, UL, RoHS, and IPC-A-600 Class 2/3 standards.

Applications Spanning Industries

Blue bare PCBs from China power a wide array of advanced technologies:

- Consumer Electronics: Smartphone motherboards, LED lighting strips, and gaming peripherals.

- Industrial Automation: Motor controllers, PLC systems, and robotics.

- Automotive: Engine control units (ECUs), battery management systems (BMS), and infotainment modules.

- Telecommunications: 5G基站 equipment, RF modules, and network routers.

- Medical Devices: Patient monitoring systems and diagnostic tools compliant with ISO 13485.

Unbeatable Cost-Efficiency

China’s vertically integrated supply chain and economies of scale enable suppliers to deliver blue bare PCBs at 20–50% lower costs than counterparts in Europe or North America—without compromising quality. Competitive pricing is bolstered by:

- Bulk Material Procurement: Reduced raw material costs.

- High-Volume Production Lines: Streamlined workflows for fast turnaround (as quick as 24 hours for prototypes).

- Flexible MOQs: Support for small-batch orders (starting at 5–10 pieces) to mass production (10,000+ units).

Sustainability and Customization

Chinese manufacturers prioritize eco-friendly practices:

- RoHS-Compliant Materials: Lead-free and halogen-free substrates align with global environmental regulations.

- Waste Reduction: Advanced CAD/CAM software optimizes panel utilization, minimizing material waste.

- Tailored Solutions: Custom specifications for layer counts, thicknesses, surface finishes, and impedance control.

Why Partner with Chinese Suppliers?

- End-to-End Expertise: From DFM (Design for Manufacturability) support to rapid prototyping and logistics.

- Scalable Production: Seamlessly transition from prototypes to high-volume orders with consistent quality.

- Global Compliance: PCBs meet international certifications for safety, performance, and environmental standards.

- Reliable Logistics: Efficient shipping with real-time tracking to destinations worldwide.

Conclusion: A Smart Choice for Modern Electronics

Blue bare PCBs from China represent the convergence of precision engineering, visual sophistication, and cost-effectiveness. Whether you’re developing cutting-edge tech or optimizing existing systems, Chinese manufacturers provide the expertise and infrastructure to meet your needs.

Explore the potential of blue bare PCBs today—connect with a certified Chinese supplier to unlock high-quality solutions that elevate your designs while staying within budget.