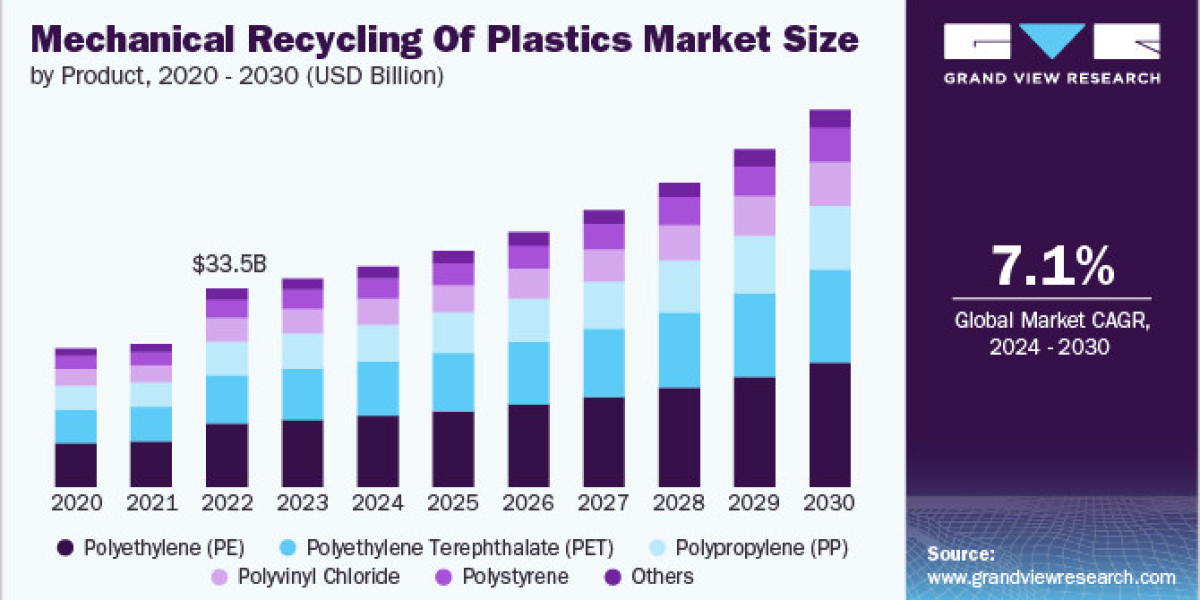

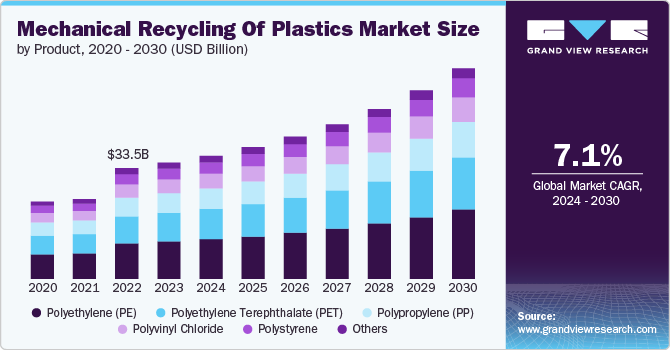

The global mechanical recycling of plastics market size was estimated at USD 35,170.05 million in 2023 and is projected to grow at a CAGR of 9.36% from 2024 to 2030. Rising non-biodegradable plastic pollution globally is increasing the threat of various ill effects caused by this pollution, leading to a surge in the demand for sustainable actions to manage plastic pollution effectively.

In recent years, the market has seen a shift towards circular economy models, where plastics are reused and recycled multiple times. Governments, particularly in Europe and North America, are pushing for stricter regulations on plastic waste management, encouraging industries to adopt sustainable recycling practices. Large consumer brands are also pledging to increase the use of recycled plastics in their packaging, boosting demand for mechanical recycling. The trend towards greater transparency and traceability in recycling processes is also growing, with companies investing in technologies that ensure the quality and purity of recycled plastics.

Get a preview of the latest developments in the Mechanical Recycling Of Plastics Market; Download your FREE sample PDF copy today and explore key data and trends

Detailed Segmentation

Product Insights

Based on product, the polyethylene (PE) segment led the market with a share of 31.96% in terms of revenue in 2023. This can be attributed to the rising global production and consumption of PE, especially in packaging, which is a significant driver for the mechanical recycling of PE plastics. PE, being one of the most commonly used plastics, contributes a substantial portion of plastic waste. Governments and regulatory bodies are setting stricter recycling targets for PE materials, particularly in the packaging sector, which relies heavily on PE for products like plastic bags, bottles, and wraps. Moreover, brand owners and retailers are committing to incorporating higher percentages of recycled PE into their products, driven by consumer demand for sustainable packaging solutions. This is increasing the need for effective mechanical recycling technologies that can process PE efficiently and produce high-quality recycled material suitable for reuse in new products.

Application Insights

Based on application, the packaging segment dominated the market with the largest revenue share of 34.36% in 2023.The push for reducing plastic waste and creating more sustainable packaging solutions is a key driver in the mechanical recycling of plastics within the packaging market. Packaging is one of the largest contributors to plastic waste, with single-use plastics being a major concern. Governments worldwide are imposing stricter regulations on the use of virgin plastics, encouraging the use of recycled materials in packaging production. In addition, global brands and retailers are committing to ambitious sustainability goals, such as using 100% recyclable or reusable packaging by 2030. This is increasing the demand for mechanical recycling solutions, which can transform post-consumer packaging waste into high-quality recycled materials, reducing reliance on virgin plastics and contributing to a more circular economy.

Regional Insights

The North America mechanical recycling of plastics market is boosted by the drive towards corporate sustainability commitments and extended producer responsibility (EPR) programs. Major consumer brands and manufacturers are facing growing pressure from both consumers and regulators to reduce their use of virgin plastics and increase the incorporation of recycled content.

Key Mechanical Recycling Of Plastics Company Insights

The market is highly competitive, with several key players dominating the landscape. Major companies include BASF, TOMRA Systems ASA, Trinseo, TotalEnergies, Eastman Chemical Company, Dow, Coperion GmbH, Covestro AG, LG Chem, and LyondellBasell Industries Holdings B.V. The market is characterized by a competitive landscape with several key players driving innovation and market growth. Major companies in this sector are investing heavily in research and development to enhance the performance, cost-effectiveness, and sustainability of their products.

Key Mechanical Recycling Of Plastics Companies:

The following are the leading companies in the mechanical recycling of plastics market. These companies collectively hold the largest market share and dictate industry trends.

- BASF

- TOMRA Systems ASA

- Trinseo

- TotalEnergies

- Eastman Chemical Company

- Dow

- Coperion GmbH

- Covestro AG

- LG Chem

- LyondellBasell Industries Holdings B.V

Mechanical Recycling Of Plastics Market Segmentation

Grand View Research has segmented Mechanical Recycling of Plastics market report on the basis of Product, Application, and Region:

- Product Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

- Polyethylene (PE)

- Polyethylene Terephthalate (PET)

- Polypropylene (PP)

- Polyvinyl Chloride

- Polystyrene

- Others

- Application Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

- Packaging

- Automotive

- Building & Construction

- Electrical & Electronics

- Textiles

- Others

- Regional Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

- North America

- U.S.

- Canada

- Mexico

- Europe

- UK

- Germany

- France

- Italy

- Spain

- Denmark

- Norway

- Sweden

- Asia Pacific

- China

- India

- Japan

- South Korea

- Australia

- Central & South America

- Brazil

- Argentina

- Middle East & Africa

- South Africa

- Saudi Arabia

- UAE

Curious about the Mechanical Recycling Of Plastics Market? Download your FREE sample copy now and get a sneak peek into the latest insights and trends

Recent Developments

- In January 2024, IIT Bombay, India announced the development of a new single screw extruding mechanical recycling machine named GolDN. It enables continuous melt mixing of waste polymers and inorganic fillers, simulating real-life processing conditions more effectively than conventional machines. This innovation significantly reduces costs, making the equipment approximately 6-8 times cheaper, at around INR 500,000 (approximately USD 6,000), by simplifying the design and utilizing local manufacturing.

- In October 2020, LyondellBasell Industries, a global player in the chemical industry, signed a Memorandum of Understanding (MoU) with Shakti Plastic Industries, India's prominent plastic recycler. This collaboration aims to establish a fully automated mechanical recycling plant in India, which will process post-consumer rigid plastic waste and produce 50,000 tons of recycled PE and polypropylene (PP) annually. This output is equivalent to the plastic waste generated by 12.5 million people.