The laser beam, a precise and concentrated form of light, has revolutionized numerous industries—from telecommunications and medical treatments to manufacturing and defense systems. Its ability to interact with materials on both macro and micro levels opens up curious questions like: Can a laser beam cut through a diamond? This question dives deep into the properties of both the laser and diamond, two entities that represent technological and natural marvels.

To answer this, we must first understand what a laser beam really is and how it interacts with different materials.

What is a Laser Beam?

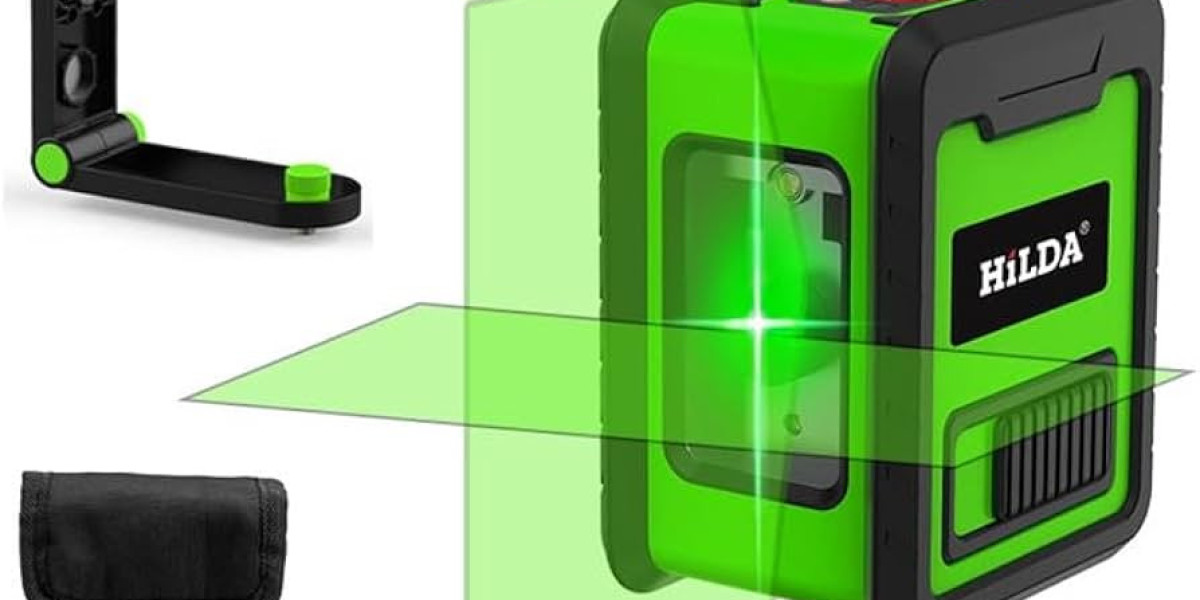

The term laser stands for Light Amplification by Stimulated Emission of Radiation. A laser beam is a narrow, highly focused stream of light that is coherent, meaning its light waves are aligned and travel in sync. Unlike regular light sources that scatter in all directions, a laser beam maintains a concentrated path, making it ideal for high-precision applications.

The strength and focus of a laser beam can vary depending on its type. Some lasers are powerful enough to engrave, weld, or even vaporize materials. These include fiber lasers, CO2 lasers, and solid-state lasers. The wavelength and energy output of the laser determines what it can interact with.

The Diamond Dilemma

Now let’s talk about diamonds. Diamonds are made from carbon atoms arranged in a unique crystal lattice that gives them their incredible hardness. They top the Mohs hardness scale at 10, making them the hardest natural substance known. This very feature makes people wonder whether even the most powerful laser beam can penetrate, cut, or alter a diamond.

Surprisingly, yes—a laser beam can cut through a diamond, but it’s not a straightforward process. The type of laser and the approach used determine whether the diamond will be cleanly cut, fractured, or vaporized.

How Does Laser Beam Interact with Diamond?

While diamonds are optically transparent in the visible light range, they have different absorption characteristics in the infrared spectrum. Many industrial lasers, such as CO2 lasers, operate in the infrared range and can be absorbed by the diamond structure, allowing precise cutting.

This principle is exploited in laser sawing and shaping of diamonds in the jewelry industry. Instead of using traditional cutting tools, manufacturers use a highly focused laser beam to cleave diamonds with exceptional accuracy. These lasers often emit pulses in the femtosecond range to minimize heat-affected zones, preserving the quality and integrity of the gem.

Industrial Applications of Laser Beam Cutting

Cutting through diamonds is just one of the many capabilities of high-powered lasers. Across various industries, the laser beam is used to cut metals, ceramics, plastics, and even biological tissues with microscopic precision. In the automotive and aerospace sectors, laser beams streamline production lines by offering clean, efficient, and contactless cutting.

In electronics, laser beam technology is used to etch circuits onto microchips and cut wafers without contamination. The food industry even uses laser beams for engraving patterns on food packaging or marking expiration dates.

What makes the laser beam so versatile is its ability to concentrate enormous amounts of energy into a minuscule area. This allows it to interact with materials that were once considered uncuttable or too fragile to handle mechanically.

Safety and Precision in Laser Operations

Because of its power and precision, working with a laser beam requires a controlled environment. Protective eyewear, shielding enclosures, and ventilation systems are often necessary in industrial settings. Even a seemingly harmless low-power laser pointer can cause eye damage if misused.

The increasing use of laser beams in surgery and dermatology also emphasizes precision and safety. Medical professionals use laser beams to perform eye surgeries, remove tumors, or even treat skin conditions, demonstrating the controlled power of this technology.

The Science Behind Laser Beam Cutting

A laser beam works by focusing light onto a specific point on the material. This light heats the area to the point of melting or vaporization. In laser cutting, an assist gas—such as oxygen, nitrogen, or air—is often used to blow the molten material away from the cut.

The speed, depth, and accuracy of the cut depend on multiple factors:

Laser power

Focused spot size

Cutting speed

Type of material

Wavelength of the beam

When cutting diamonds, ultrafast lasers are preferred. These operate in pulses so short (femtoseconds) that they remove material before heat can even diffuse into the surrounding structure. This allows for cold ablation—material removal without heat damage.

Custom Laser Solutions for Modern Businesses

For businesses involved in manufacturing, engraving, or precision engineering, investing in a laser beam system is becoming increasingly necessary. Modern systems can be tailored for specific applications, from engraving logos on jewelry to slicing through composite metals.

Companies offering laser machines often provide modular solutions, training, and support to ensure seamless integration. Whether you're in textiles, automotive, electronics, or luxury goods, there's a laser system designed to meet your needs.

From micromachining to heavy-duty industrial cutting, the laser beam has positioned itself as a tool that matches the speed and precision modern production demands.

Why Laser Beam Technology is Evolving Rapidly

As materials evolve and products become smaller and more intricate, laser beam systems are advancing in parallel. Fiber lasers, for instance, are now more energy-efficient and require less maintenance. Hybrid systems are emerging, combining laser cutting with robotics and AI-based controls to optimize processes.

Educational institutions are even beginning to incorporate laser beam technology in their research labs, training future generations to harness this powerful light in innovative ways.

Final Thoughts

So, can a laser beam cut through a diamond? Absolutely. The toughest natural material in the world meets its match in a stream of concentrated light. This isn't just a technical feat—it's a symbol of how human innovation continues to push the limits of what is possible.

Whether you’re crafting intricate jewelry or cutting titanium sheets for jet engines, the laser beam is more than a light—it’s a transformative tool. Its ability to handle the most delicate and the most durable of materials makes it one of the most important technologies in modern industry. As developments continue, there’s no doubt the laser beam will continue to illuminate new frontiers across science, art, and manufacturing.