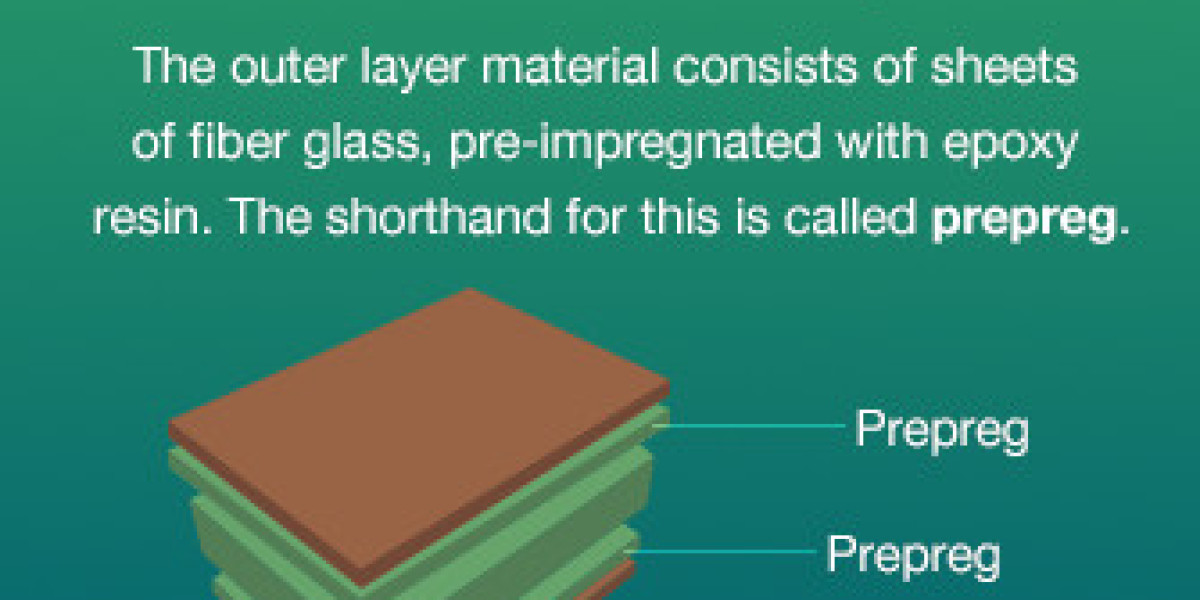

Prepreg refers to a type of insulating layer used during the production of printed circuit boards (PCBs). It is a dielectric material placed between two inner cores or between a copper foil and a core, playing a critical role in ensuring insulation. Within multilayer PCBs, it functions as the bonding medium between copper layers, providing both mechanical reinforcement and electrical isolation. It also assists in tailoring specific electrical characteristics, like controlled impedance, based on its dielectric constant.

In multilayer board assemblies, prepreg acts as a stabilizing medium between layers, ensuring alignment and structural consistency. Its correct application enhances overall performance, minimizing signal interference and optimizing high-frequency functionality. The properties—such as resin type and layer thickness—are selected based on the desired electrical and mechanical requirements. This importance is reflected in the expanding global demand for prepreg, with the market experiencing over 12% annual growth.

Core Concepts

Prepreg materials are typically composed of fiberglass fabric impregnated with resin, widely applied in specialized boards such as Burn-In Boards. The production process includes impregnation, partial curing (B-stage), trimming, and precise packaging—each stage impacting its performance.

Choosing the right prepreg involves evaluating several factors like thermal durability, signal transmission integrity, and resin composition. Prepreg differs from laminate in that it is only partially cured, whereas laminates are fully cured fiberglass sheets with copper on one or both surfaces.

Common Types of Prepreg:

- Standard FR4

- High Tg Prepreg

- PTFE Composites

- Polyimide Prepreg

- Aramid-based Nonwoven Prepreg

Why Prepreg is Vital in Layered PCB Designs

Prepreg serves as the adhesive matrix in multilayer PCBs, joining copper and insulating layers into a cohesive structure. This adhesive function is vital for ensuring physical stability and signal reliability across the stack.

Additionally, prepreg materials offer precise control over the dielectric environment of each layer, crucial for designs involving high-speed signal transmission. Their customizable thickness and resin content allow manufacturers to fine-tune interlayer spacing and impedance levels, resulting in better signal clarity and reduced electromagnetic interference.

Role in PCB Layer Lamination

During lamination, heat and pressure cause the semi-cured resin in prepreg to melt and flow, filling voids between layers and solidifying into a unified board structure. This not only enhances durability but also prevents delamination over time, ensuring long-term performance in complex electronics.

If you have any questions for PCB, please feel free to contact me--Perlina. We can provide 24-hour online answering service.We Hitech are always here to support you. Want to know more about our products, you can enter our website hitechcircuits.com.