Manufacturing Process of Copper Core PCBs

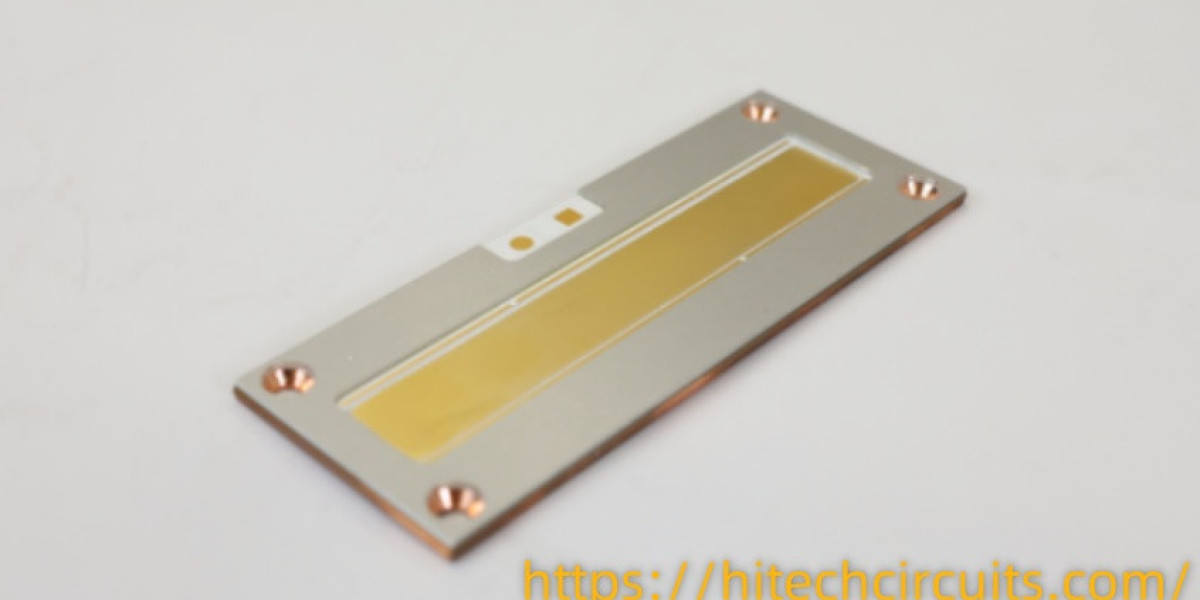

Copper core PCBs belong to the metal core PCB family and feature a multi-layer structure built on a copper substrate. This construction provides outstanding heat conduction capabilities.

Base Layer: Constructed with copper, this layer delivers excellent thermal performance and efficient heat dissipation.

Insulation Layer: Prepreg or similar high-conductivity insulating material is used to further boost thermal management.

Circuit Layer: Made from copper foil, typically ranging from 1 to 10 ounces in weight.

Dielectric Layer: This layer functions as a thermal path, channeling heat from the circuit layer to the copper base for dispersal.

Benefits of Using Copper Core PCBs

Compared to standard PCBs, metal core variants like copper-based boards offer several advantages. The use of copper enhances the board’s overall reliability and function.

Superior Heat Dissipation

Copper stands out among metal core materials for its high thermal conductivity. This property allows for efficient heat spread and dissipation. In high-temperature settings, traditional boards like FR-4 may suffer damage, while copper core PCBs can protect sensitive circuits, maintaining performance and prolonging device life.

Eco-Friendly Material

Copper is a natural and fully recyclable material, making these PCBs a more sustainable option.

Long-Lasting Performance

Due to their improved heat management, copper core PCBs are more resistant to warping or corrosion over time. They also endure manufacturing stress better than typical board materials, reducing the risk of damage during production or daily use.

Common Applications

Thanks to their ability to handle high temperatures and dissipate heat efficiently, copper core PCBs are well-suited for high-power applications. They ensure the integrity of circuits under extreme thermal conditions.

Originally used in high-power switching power supplies, these boards are now widespread in LED technology and other applications demanding high thermal reliability. Their structure supports complex and compact layouts operating under significant electrical loads.

Examples include:

Lighting: Used in street lamps, indoor lighting, and portable lanterns.

Automotive: Found in headlights and electronic control modules.

Telecom: Ideal for signal filters and high-frequency amplifiers.Audio Equipment: Used in power, input, and output amplifiers.

Computing: Suited for CPUs and power management components.

Power Electronics: Employed in converters, relays, rectifiers, and bridge circuits.

Medical Devices: Found in surgical lighting systems, high-power scanning tools, and medical-grade converters.

Hitech Circuits can supply high-quality copper core PCBs tailored to your project needs. To get started, send your Gerber files to sales3@hitechcircuits.com.