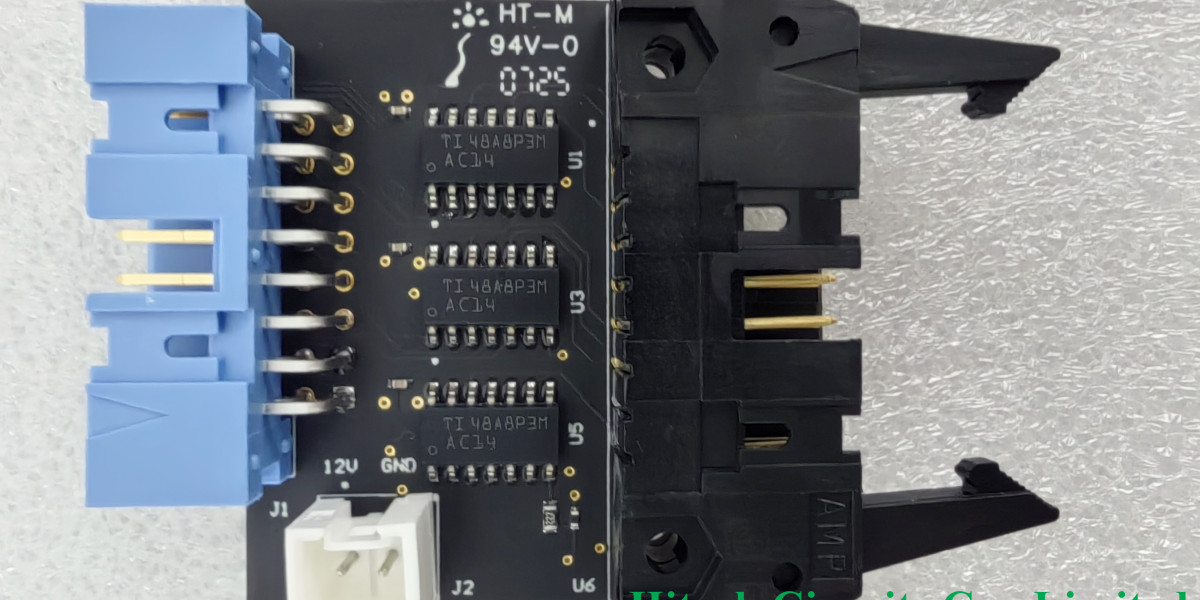

Black PCBA: China’s Smart Manufacturing Empowers Global Robotic Assistance Industry

In recent years, the robotic assistance industry has emerged as a critical frontier in global technological competition, driven by advancements in artificial intelligence, the Internet of Things, and automation. At the heart of this revolution lies the Printed Circuit Board Assembly (PCBA), often dubbed the "brain and nervous system" of electronic devices. Its performance and reliability directly determine the intelligence and efficiency of robotic systems. Among these components, black PCBA—manufactured with precision in China—has become a cornerstone of the global robotics supply chain, combining cutting-edge technology with cost-effective production. Pls send PCB files to sales1@hitechpcb.com to get a quote now!

- Black PCBA: Where Technology Meets Aesthetics

While traditional green or blue PCBA remains widely used, black PCBA has gained prominence for its technical superiority and sleek design:

- Enhanced Anti-Interference and Thermal Management: The black solder mask offers superior light-blocking properties, reducing electromagnetic interference (EMI) during high-frequency signal transmission. Its dark coating also accelerates heat dissipation, making it ideal for robots requiring prolonged operation.

- Durability in Harsh Environments: Through advanced manufacturing processes, black PCBA exhibits exceptional resistance to moisture, corrosion, and mechanical stress. This durability is critical for industrial robots, medical assistance robots, and outdoor service robots.

- Aesthetic Versatility: The sleek black finish allows seamless integration with modern robotic designs. For instance, service robots with metallic exteriors leverage black PCBA to project a premium, futuristic appearance.

- Made in China: From Mass Production to Technological Leadership

China, the world’s largest electronics manufacturing hub, has transformed its PCBA industry from a low-cost assembler to a global innovator. In the realm of black PCBA, three key strengths underpin China’s dominance:

- Scale and Cost Efficiency: Clusters in the Pearl River Delta and Yangtze River Delta enable rapid mass production. Automated assembly lines reduce costs by over 30% while maintaining a defect rate below 0.1%.

- Cutting-Edge R&D: Collaborations between tech giants like Huawei, BYD Electronics, and leading universities have propelled advancements in surface-mount technology (SMT), enabling micron-level circuit precision. Innovations such as embedded AI chips and 5G modules further enhance functionality.

- Global Compliance: Chinese manufacturers adhere to stringent international standards, including ISO 13485 (medical devices) and IPC-A-610 (electronic assemblies), ensuring black PCBA meets the demands of high-stakes applications like surgical robots and aerospace automation.

III. Applications: Powering Diverse Robotic Innovations

Black PCBA "Made in China" is driving breakthroughs across industries:

- Industrial Automation: In BYD’s smart factories, robotic arms equipped with black PCBA execute nanoscale precision tasks in automotive assembly lines, supported by EMI-resistant circuitry for 24/7 reliability.

- Healthcare Robotics: Shenzhen-based medical robots utilize black PCBA control modules to perform minimally invasive surgeries, where low-latency signal transmission and heat management are life-critical.

- Logistics and Service: JD Logistics’ warehouse robots, powered by customized black PCBA, navigate complex environments using integrated vision systems and AI algorithms, improving efficiency by 40%.

- Challenges and the Road Ahead

Despite China’s leadership, two challenges loom:

- Dependence on Imported Materials: High-performance solder masks and thermally conductive substrates still rely on suppliers from Japan and South Korea, highlighting the need for domestic material innovation.

- Geopolitical Pressures: Policies like the U.S.’s "Reshoring Initiative" and the EU’s supply chain regulations threaten to fragment global production networks. For example, Tesla’s Optimus robot project mandates PCBA production in North America.

To sustain its edge, China is prioritizing:

- Collaborative R&D: Partnerships with institutions like Tsinghua University aim to develop nano-coatings and energy-efficient designs.

- Green Manufacturing: Adoption of lead-free processes and recyclable materials aligns with global sustainability mandates, such as the EU’s New Battery Regulation.

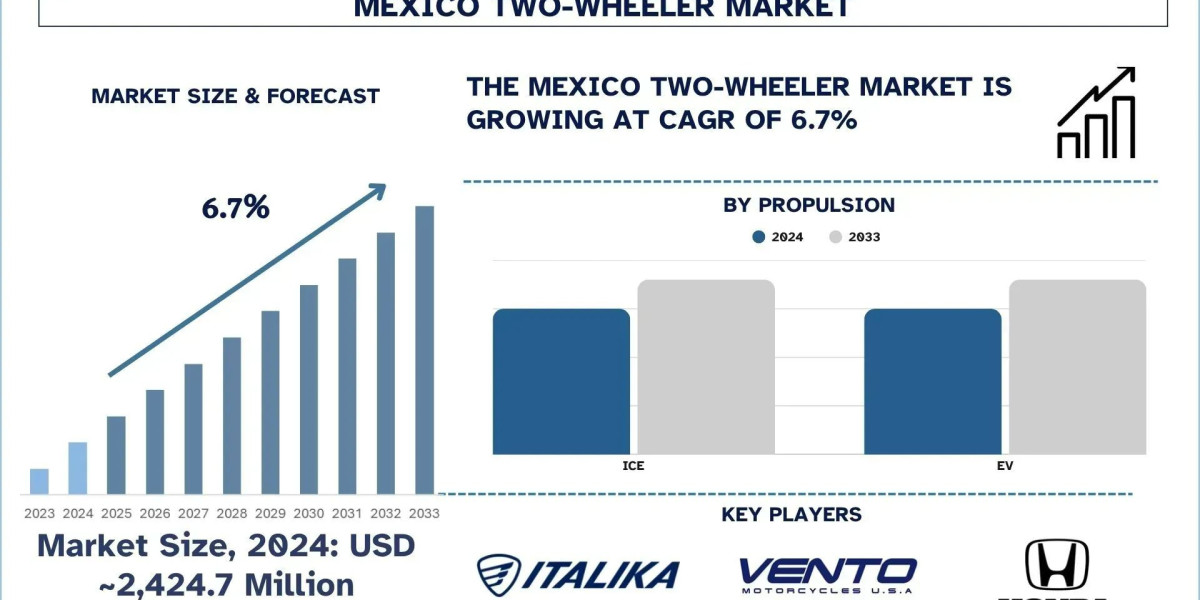

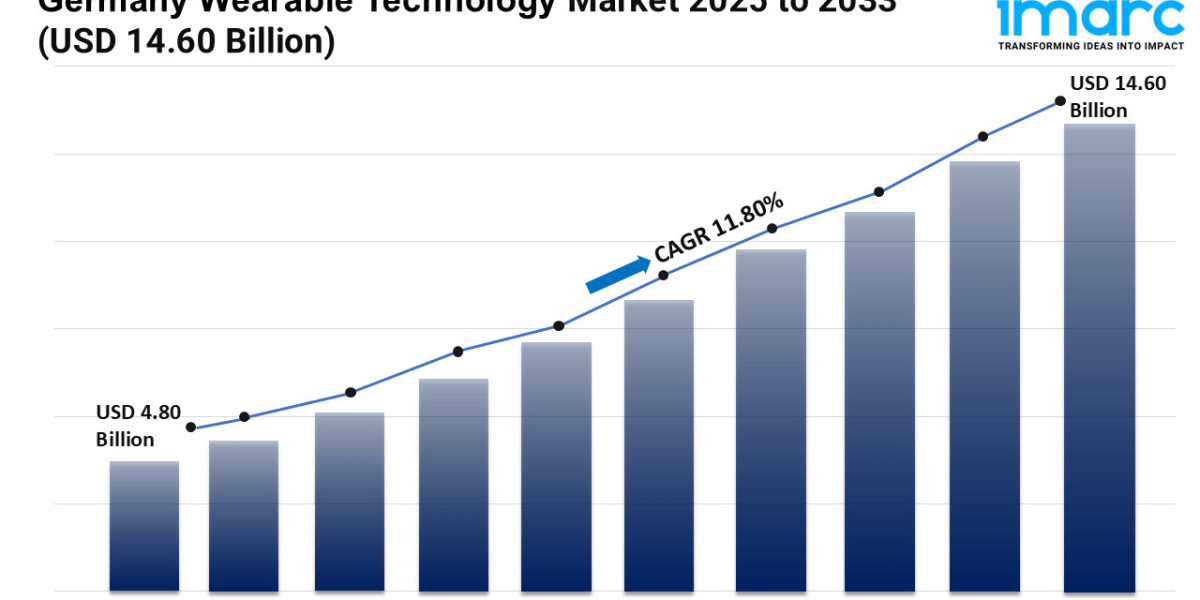

- Global Expansion: Building factories in Southeast Asia and Mexico to bypass trade barriers and cater to regional markets.

Conclusion

Black PCBA epitomizes China’s evolution from a manufacturing powerhouse to a global technology innovator. As robotics permeates industries from healthcare to smart cities, China’s expertise in producing high-performance, cost-effective PCBA positions it as an indispensable partner in shaping the future of automation. With continued investment in R&D, sustainability, and global collaboration, the "black core" of robotics—forged in China—will remain a catalyst for redefining human-machine collaboration worldwide.

In the coming decade, as robots powered by Chinese-engineered PCBA become ubiquitous, the world may witness not just a technological leap, but a new era of intelligent connectivity—one circuit board at a time.

https://hitechcircuits.com/pcb-assembly/