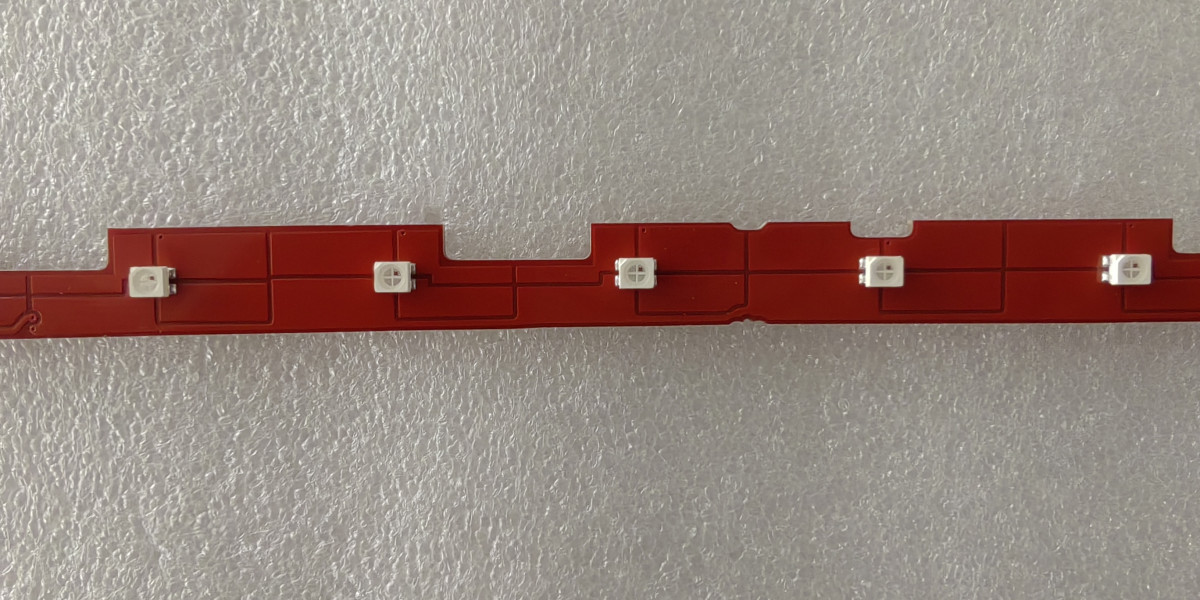

Red Strip LED PCBA Boards for Automobile Brake Systems: Safety and Reliability Engineered in China

In the automotive industry, where safety and durability are non-negotiable, red strip LED PCBA (Printed Circuit Board Assembly) boards have become indispensable components in modern brake systems. These specialized boards power high-visibility brake lights, ensuring clear communication between vehicles and enhancing road safety. Chinese manufacturers, renowned for their precision engineering and cost-efficient production, are driving innovation in this critical sector. This article explores how China’s expertise in automotive-grade LED PCBA technology delivers high-performance solutions for global automakers. Please send PCB files to sales1@hitechpcb.com to get a quote now!

The Role of Red Strip LED PCBA Boards in Brake Systems

Red strip LED PCBA boards are integrated into vehicle brake lights, particularly in third brake lights (CHMSL – Center High-Mount Stop Lamps) and rear light clusters. Their primary functions include:

- Instant Illumination: LEDs provide rapid response times (<1 ms), crucial for alerting drivers during sudden braking.

- High Brightness & Uniformity: Ensure visibility in all weather conditions (e.g., fog, rain, or bright sunlight).

- Energy Efficiency: LEDs consume less power compared to traditional incandescent bulbs, reducing strain on vehicle batteries.

- Longevity: With lifespans exceeding 50,000 hours, they outlast conventional bulbs, minimizing maintenance needs.

These boards are engineered to meet stringent automotive standards, including resistance to vibration, temperature extremes, and electrical surges.

Why Choose Chinese-Made Red Strip LED PCBA Boards?

China’s automotive electronics sector combines cutting-edge technology with rigorous quality control, making it a trusted partner for global OEMs and Tier-1 suppliers. Here’s why Chinese manufacturers excel:

- Automotive-Grade Design and Materials

- Robust Substrates: Use of high-temperature FR-4, aluminum-core PCBs, or ceramic-filled laminates to withstand engine compartment heat (up to 125°C+).

- Premium LEDs: Sourced from top-tier suppliers, offering high luminous intensity (≥1000 mcd) and consistent color temperature (630–660 nm wavelength for pure red).

- Protective Coatings: Conformal coatings (silicone, acrylic) guard against moisture, dust, and chemical corrosion.

- Advanced Manufacturing Processes

- Automated SMT Assembly: High-speed pick-and-place machines ensure precise mounting of LEDs, resistors, and drivers.

- Reflow Soldering: Optimized profiles prevent thermal stress on components.

- Automated Optical Inspection (AOI): Detects soldering defects, misaligned components, or trace imperfections.

- Compliance with Automotive Standards

Chinese suppliers adhere to critical certifications:

- AEC-Q101: Qualification for LED components in automotive environments.

- IATF 16949: Quality management for automotive production.

- ISO 16750: Compliance for vibration, shock, and temperature resistance.

- IP67/IP69K: Dust and water resistance for outdoor durability.

- Customization for Specific Applications

- Flexible Form Factors: Boards tailored to fit curved or compact brake light housings.

- Dimming and Control Integration: Compatibility with CAN/LIN bus systems for adaptive brake lighting.

- Smart Features: Integration with sensors for fault detection or adaptive brightness based on ambient light.

- Cost-Effective Scalability

China’s integrated supply chain and economies of scale enable competitive pricing without compromising quality. Bulk production capabilities ensure timely delivery for high-volume automotive orders.

Key Applications in Automotive Brake Systems

- Third Brake Lights (CHMSL)

- Slim, high-intensity LED strips mounted on rear windshields or spoilers.

- Customizable lengths and brightness levels to match vehicle designs.

- Rear Light Clusters

- Integrated PCBA boards for combined brake/tail/turn signal functions.

- Dynamic lighting patterns (e.g., scrolling effects for enhanced visibility).

- Advanced Driver Assistance Systems (ADAS)

- Synchronization with emergency braking systems to flash lights during rapid deceleration.

- Electric and Autonomous Vehicles

- Low-power designs compatible with EV battery systems.

- Fail-safe circuits for autonomous vehicle communication.

Case Study: Enhancing Safety for a European EV Manufacturer

A leading European electric vehicle brand partnered with a Chinese PCBA supplier to develop a red strip LED brake light system. The design incorporated:

- Aluminum-core PCBs for superior heat dissipation in high-density battery compartments.

- PWM Dimming Control to adjust brightness based on ambient light, reducing glare for following drivers.

- Vibration-Resistant Soldering to endure rough road conditions.

The result? A 25% improvement in heat management, 15% energy savings, and compliance with ECE R7 and FMVSS 108 safety standards—showcasing China’s ability to meet global automotive demands.

Quality Assurance and Testing

Chinese manufacturers implement rigorous validation processes:

- Thermal Cycling Tests: Expose boards to -40°C to +125°C cycles to simulate extreme climates.

- Vibration and Shock Testing: Mimicate road conditions per ISO 16750-3 standards.

- Salt Spray Testing: Ensure corrosion resistance for coastal or winter road environments.

- Electrical Stress Testing: Validate performance under voltage spikes (e.g., load dump scenarios).

Why Partner with Chinese Suppliers?

- End-to-End Solutions: From PCB fabrication to full assembly and testing.

- Prototyping Speed: Functional samples delivered in 7–10 days.

- Global Logistics Support: Seamless shipping to automotive hubs in Europe, North America, and Asia.

- Sustainability Focus: RoHS-compliant materials and energy-efficient production practices.

Conclusion

Red strip LED PCBA boards are vital for modern vehicle safety, and China’s automotive electronics industry is at the forefront of delivering reliable, innovative, and cost-optimized solutions. By leveraging advanced manufacturing technologies, adherence to global standards, and a deep understanding of automotive needs, Chinese suppliers empower automakers to create safer, smarter, and more efficient vehicles.

Drive Safer. Choose Precision. Trust Red Strip LED PCBA Boards from China.

For more, please visit https://hitechcircuits.com/pcb-assembly/.