The global market for selective laser sintering (SLS) equipment is experiencing rapid expansion, with an estimated value of USD 572.6 million in 2023. This market is poised for significant growth, projected to achieve a remarkable compound annual growth rate (CAGR) of 23.7% from 2024 to 2030.

A major catalyst for this market surge is the escalating demand for customization and personalization across diverse industries. Consumers are increasingly seeking products precisely tailored to their unique needs and preferences. This trend is prompting manufacturers to embrace SLS technology, enabling the on-demand production of highly intricate and bespoke components. This not only satisfies evolving consumer demands but also empowers manufacturers to stand out and differentiate their offerings in competitive markets.

Technological advancements are also playing a pivotal role in boosting SLS equipment demand. As SLS technology continues to evolve, manufacturers are consistently refining processes, enhancing precision, and broadening the spectrum of compatible materials. These innovations not only improve the performance and versatility of SLS equipment but also contribute to its cost-effectiveness, making it an increasingly attractive option for a wide array of applications.

Get a preview of the latest developments in the Selective Laser Sintering Equipment Market; Download your FREE sample PDF copy today and explore key data and trends

Furthermore, the growing emphasis on cost efficiency is driving companies to explore alternative manufacturing methods like SLS. While the initial investment for SLS equipment can be substantial, the technology delivers significant long-term cost savings through reduced material waste, lower tooling expenses, and improved production efficiency. As businesses strive to optimize their manufacturing processes and streamline workflows, the demand for SLS equipment is expected to augment in the coming years.

Finally, the environmentally friendly nature of SLS technology is gaining increasing importance for companies committed to sustainable manufacturing solutions. SLS equipment generates less waste compared to conventional manufacturing methods and supports the use of recyclable materials, aligning perfectly with the growing industry focus on sustainability.

Detailed Segmentation

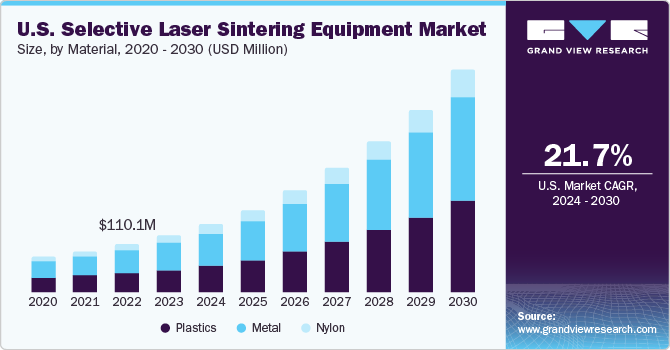

Material Insights

The metal segment held the largest revenue share of 45.7% in 2023. The use of metal materials in SLS equipment opens up a wide range of application opportunities across various industries, including aerospace, automotive, healthcare, and industrial manufacturing. Metal parts produced using SLS technology are required to meet stringent requirements for strength, durability, and performance, making them suitable for end-use applications in demanding environments.

Laser Type Insights

The gas laser type segment held the largest revenue share in 2023. Gas lasers offer versatility in material processing, enabling the sintering of a wide range of materials, including polymers, metals, ceramics, and composites. This versatility allows SLS equipment with gas lasers to cater to diverse industries and applications, thereby expanding its market potential.

Technology Insights

The industrial printer technology segment held the largest share in 2023. Industrial SLS printers typically feature large build volumes, allowing for the production of large and complex parts in a single build. This scalability enables manufacturers to optimize production efficiency and accommodate diverse part sizes and geometries, making industrial SLS printers suitable for a wide range of applications.

End-use Insights

The automotive segment dominated the market and accounted for 23.1% in 2023. The automotive industry is increasingly focused on lightweight vehicles to improve fuel efficiency and reduce emissions. SLS technology enables the production of lightweight, yet durable components by using advanced materials like carbon fiber-reinforced polymers and metal alloys. These lightweight parts contribute to overall vehicle weight reduction, enhancing fuel efficiency and sustainability.

Regional Insights

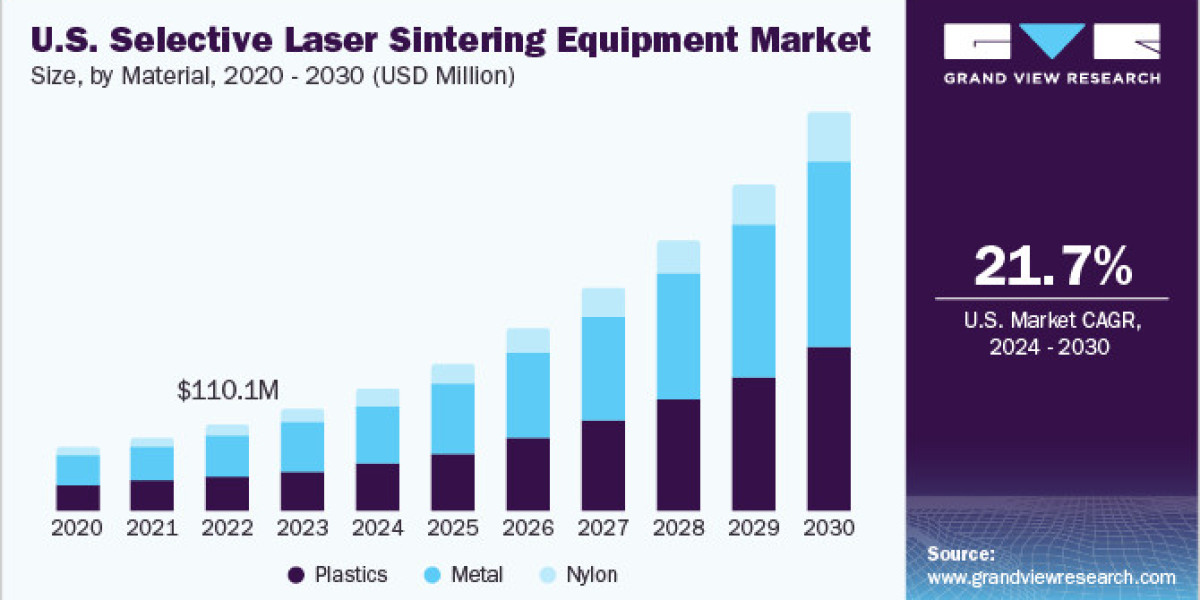

North America dominated the market and accounted for 36.3% in 2023. The region boasts a mature and advanced manufacturing ecosystem, particularly in industries such as aerospace, automotive, healthcare, and consumer goods. The demand for innovative manufacturing technologies like SLS is driven by the need for rapid prototyping, customization, and production of complex components, aligning well with the capabilities of SLS equipment.

Key Selective Laser Sintering Equipment Companies:

The following are the leading companies in the selective laser sintering equipment market. These companies collectively hold the largest market share and dictate industry trends.

- 3D Systems Inc.

- EOS GmbH

- Farsoon Technologies

- Prodways Group

- Formlabs Inc.

- Ricoh Company Ltd

- Concept Laser GmbH (General Electric)

- Renishaw PLC

- Sinterit Sp. Zoo

- Sintratec AG

- Sharebot SRL

- Red Rock SLS

- Natural Robotics

- Z Rapid Tech

- Aerosint

Selective Laser Sintering Equipment Market Segmentation

Grand View Research has segmented the global selective laser sintering equipment market based on material, laser type, technology, end-use, and region:

Selective Laser Sintering Equipment Material Outlook (Revenue, USD Million, 2018 - 2030)

- Metal

- Plastics

- Nylon

Selective Laser Sintering Equipment Laser Type Outlook (Revenue, USD Million, 2018 - 2030)

- Solid Laser

- Gas Laser

Selective Laser Sintering Equipment Technology Outlook (Revenue, USD Million, 2018 - 2030)

- Desktop Printer

- Industrial Printer

Selective Laser Sintering Equipment End-use Outlook (Revenue, USD Million, 2018 - 2030)

- Automotive

- Aerospace & Defense

- Healthcare

- Electronics

- Others

Selective Laser Sintering Equipment Regional Outlook (Revenue, USD Million, 2018 - 2030)

- North America

- U.S.

- Canada

- Mexico

- Europe

- UK

- Germany

- France

- Italy

- Spain

- Asia Pacific

- China

- Japan

- India

- South Korea

- Singapore

- Central & South America

- Brazil

- Middle East & Africa

Curious about the Selective Laser Sintering Equipment Market? Download your FREE sample copy now and get a sneak peek into the latest insights and trends

Recent Developments

- In June 2022, 3D Systems and EMS GRILTECH announced a strategic partnership to enhance additive manufacturing materials development. Both companies planned to introduce a novel nylon copolymer DuraForm PAx Natural- designed to be used with any commercially-available selective laser sintering (SLS) printer.